Drill Pearls in Any Sized Holes, Any Way You Want

Top Drill, Center Drill, Half Drill or Fully Drilled, to Undrilled

Since we have got pearls straight from our pearl farm, we can drill any shaped pearls in any way you would like. Our workers can drill pearls, beads, Briolats and gemstones so you can hung or use on necklaces, earrings and other jewellery pieces. This is done using different types of drilling tools like the ultrasonic drilling machine to make an accurate hole.

Since we have got pearls straight from our pearl farm, we can drill any shaped pearls in any way you would like. Our workers can drill pearls, beads, Briolats and gemstones so you can hung or use on necklaces, earrings and other jewellery pieces. This is done using different types of drilling tools like the ultrasonic drilling machine to make an accurate hole.

Any Sized Holes – We can drill standard hole size or any larger hole size at 1mm, 2mm, 2.5mm, 3mm or even larger…

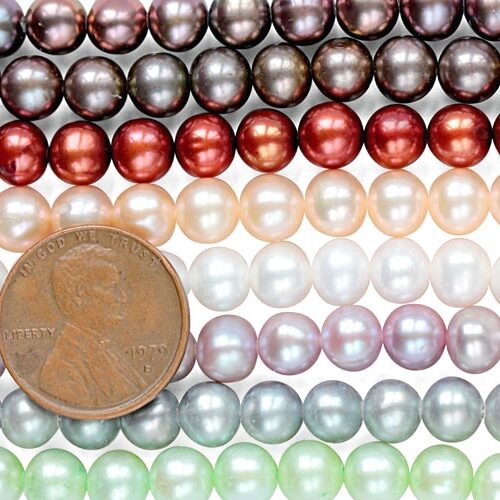

Any Shaped Pearls – Round, baroque, rice, potato, Keshi, Biwa, coin, cross, button, peanut pearls are all available…

Drill in Any Way – From half drill, to fully drilled or double drilled, to top drilled, diagonally drilled or undrilled…

Drill any shaped pearls in any way you want:

Half drilled pearl is used for making pearl earrings, rings, pendants, tie tacks, brooches and other jewelery pieces. This process is when the hole is only halfway through the pearl. The fact is that drilling is delicate work.

Because pearls are very fragile and can break during the drilling process so you should trust the experts with your pearls. Many times, the ultrasonic drilling is the best method for the harder jobs. The harder and more brittle materials can overheat and then crack with the rotating drilling. The very small holes in the harder materials will take better to the ultrasonic drilling.

We are the experts in drilling pearls, that’s why we cannot only top drill, side drill, half drill but also fully drill your pearls or gemstones in any way you want. Basically, there are two types of drilling pearls, one is full-drilling, and the other is half-drilling.

Full drilling involves making a hole that goes through a cultured pearl. People use them to make the necklaces or bracelets when pearl strand has to pass through the pearl.

The pearl is drilled from two sides to get the hole. If we drill the pearl wiith one long bit, it could damage or break the pearl. You will also need a drill piece to hold and align your pearl. This is long and has a base at one end and a clamping piece on the other side.

Drilled pearls in any hole size:

The pearl gets sandwiched between two concave seats on opposite ends of bushings in alignment. They can be clamped in an upright or inverted position as long as they are aligned with the drill bit. Get the pearl right in the middle of the position, and choose the right sized bit you want to sit in the machine, like 1mm or 2.5mm bit. Drilling pearls has evolved over the years. The machines and processes have improved.

A: 0.9mm hole is for pearls over 5mm,

B: 1.3mm hole is for pearls over 6mm,

C: 1.7mm hole is for pearls over 8mm and

D: 2.3mm hole is for pearls over 9mm

Pearl drilling is a delicate situation, and the drill points have to have the proper shape and should be blunt and a somewhat a V-shape. The drill should have the proper revolutions so it doesn’t jolt the pearl. If the drill breaks in the pearl, then drill opposite to remove the broken piece. In the old days people make the pearls with bow drills by holding the hand. Drilling pearls used to only produce a few hundred and now we are into producing well over a thousand per sitting. Please note Mabe pearls cannot be drilled at bigger or smaller size.

-

6-7mm AA Quality Round Pearl Strand 1.5mm hole

$49.99 Select options This product has multiple variants. The options may be chosen on the product page -

12-14mm Huge Near-Round Pearls Pre-Drilled 1.7-2.5mm Holes on Strand

$79.99 – $129.99 Select options This product has multiple variants. The options may be chosen on the product page -

9-10mm Semi-Round Pearl Strands with Larger Holes

$14.99 Select options This product has multiple variants. The options may be chosen on the product page

-

5-6mm AA+ Round White Pearl Strand Pre-drilled 0.9mm Larger Hole

$47.99 Select options This product has multiple variants. The options may be chosen on the product page -

Huge 12-13mm Rice Pearl Strand with Natural Dents 2.3mm hole

$29.99 Select options This product has multiple variants. The options may be chosen on the product page

-

Loose Biwa Pearls in White Pink and Mauve

$4.49 Select options This product has multiple variants. The options may be chosen on the product page -

5-7mm Loose Drop Pearls Undrilled or Half-drilled

$0.59 Select options This product has multiple variants. The options may be chosen on the product page -

Un-drilled Cross Shaped Loose Individual Pearl 1in by 2in Size

$9.99 Select options This product has multiple variants. The options may be chosen on the product page

Drill the Pearls in Any Way

As you may know, some of the best needles are made out of thin steels and ground flat. They will prevent clogging and allow the fine dust to pass up and out. There are those who think the drill should be lubricated with milk! However, if the drill is well made you don’t have to do this. There are times when the driller will hit the hard kernel in the center of the pearl which could be a grain of sand and the drill will break. The first drills were hot copper drills. There is also the bow and fiddle drill that is still used to this day.

For any of the pearl strands we are selling, if you would like to have your pearls drilled in other sized holes or in different directions, please email us at [email protected].